The shortage of semiconductors is also slowing car production at Volkswagen. A Volkswagen spokesperson said Thursday that Volkswagen’s main plant in Wolfsburg can only be restarted to a limited extent after next week’s summer break. Production takes place in only one shift on all production lines, and short-time work is required.

“The ever-restricted delivery mode of semiconductors continues to cause significant disruptions to global automotive production across all manufacturers.”

The outbreak of the Covid virus in Asia has again led to factory closures at semiconductor manufacturers, for example in Malaysia. Volkswagen Group assumes chip supply in the third quarter will remain volatile and tense. Therefore, further production modifications cannot be ruled out.

“By the end of the year, Volkswagen expects an overall improvement in semiconductor supply. We intend to offset the production backlog as much as possible in the second half of the year,” the automaker added. The set assumes that the six-digit number of vehicles will be affected by the delays.

Short time work at Audi

At the Audi in Ingolstadt and Neckarsulm, about 10,000 employees have to extend their summer vacation and work for a short time due to the lack of semiconductors. As a company spokesperson said Thursday, the planned several thousand vehicles cannot be built.

“Total coffee aficionado. Travel buff. Music ninja. Bacon nerd. Beeraholic.”

More Stories

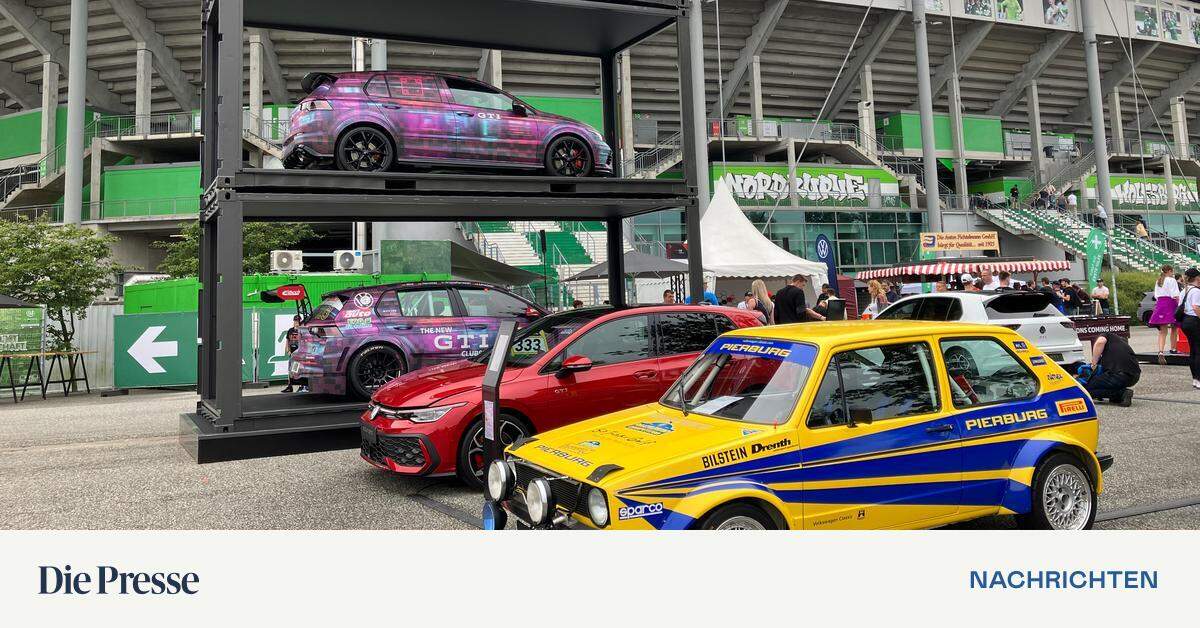

Wolfsburg instead of Wörthersee: The first GTI meeting starts at Volkswagen headquarters

Pecco Bagnaia (Ducati): Testing on the new Panigale/MotoGP

From autumn onwards, U2 will be playing again at Karlsplatz.