In 2023, more recyclables will find their way to IDs ID.3, ID.4, ID.5 and ID.7 – Volkswagen relies on old materials recycled from PET bottles

Pure electric identity. Vehicles are becoming more sustainable. This also applies to the choice of materials in the interior. ID.3, ID.4, ID.5 and ID.701 will get select innovations this year, which will be introduced for the first time with the ID. Buzz02 has entered mass production.

Seat covers example: Here, Volkswagen uses Seaqual® yarn, which is made from 10 percent marine collected waste and 90 percent recycled PES yarn. CO2 emissions during production are approximately one third lower than conventional surfactants.

Silke Bagschik, Head of E-Mobility Series, explains: “Through the extensive use of recycled materials and a leather-free interior in our ID models, we continue to improve the environmental balance of our cars – with high standards for long-term value and quality. Feedback from our customers encourages us to Expand these sustainable approaches in the future.”

Identification card. Buzz is at the forefront of recycling innovation

within the identity. Buzz, Volkswagen is already using several new materials, which are now gradually being used in other models of the id. Bring the family. Inside the new Polly, alternative materials made from sea plastic or old PET bottles (to be exact 63 pieces of 500ml each) are used in many places. The seat cover consists of the so-called ID. Family upper made with Seaqual® yarn made from 10 percent marine debris collected and 90 percent recycled PES yarn. This saves 32 percent of CO2 emissions in production compared to conventional roofing materials. In seat covers with ArtVelours Eco®, the recycled content is 71 percent. In addition, the upper lining surfaces and the floor mat are in ID. Buzz is made from 100% recycled polyester. The carpet underlayment also contains recycled plastics. The same applies to components such as skid plates and wheel arch liners.

In addition, Volkswagen uses door veneers, instrument panel and steering wheel bezels in the ID. No more chromium, the production of which is harmful to the environment. An alternative is to use a liquid chrome-effect paint with a bio-binding agent. Some of these recycling innovations from id. Buzz will now find its way to ID.3, ID.4, ID.5 and ID.7.

Recycled as a fully functional replacement

Recycled materials are old, processed materials that are reused in new products. In the case of plastics, these are, for example, PET bottles or old fishing nets. This plastic waste is processed into granules and can then be reused. Depending on requirements, components can consist of a small percentage or entirely of recycled materials. Indoors, re-circulation materials must always have the same properties as conventional materials. This affects its appearance and feel on the one hand, and its durability and longevity on the other.

On the way to zero

By 2030, Volkswagen aims to reduce CO2 emissions per vehicle by 40 percent, and the company wants to be climate-neutral by 2050 at the latest. In order to achieve these goals, Volkswagen analyzes and optimizes the entire life cycle of vehicles: from basic research through development and production to recycling at the end of their useful life. Volkswagen strives for closed material cycles for all raw materials used.

Article put online by: / Doris Holler /

“Total coffee aficionado. Travel buff. Music ninja. Bacon nerd. Beeraholic.”

More Stories

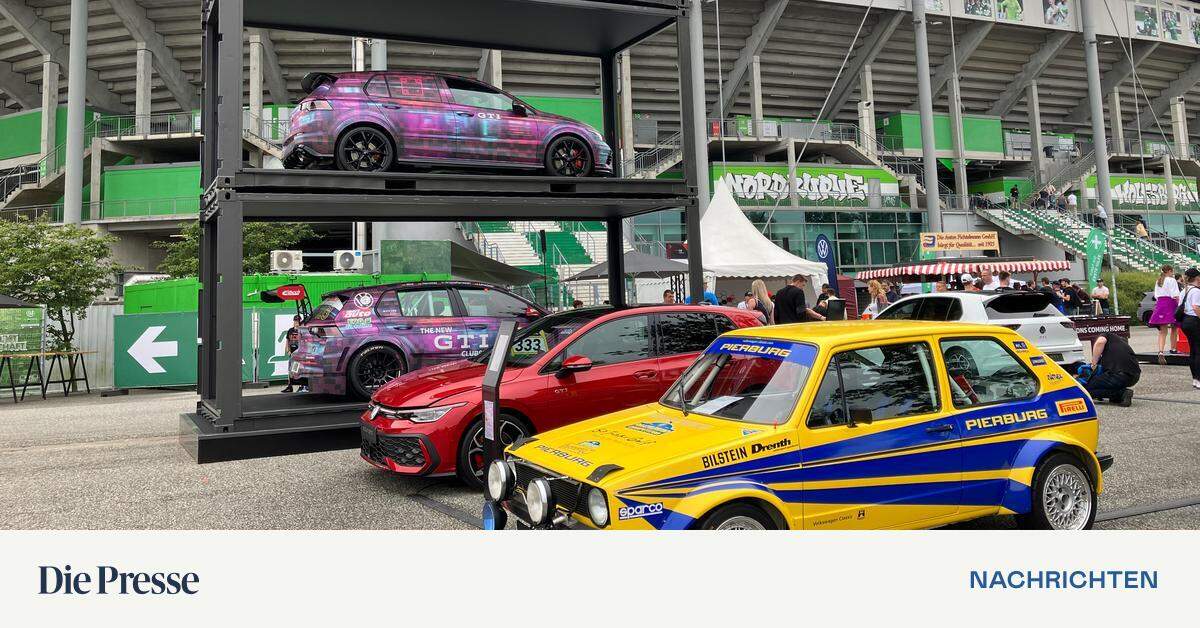

Wolfsburg instead of Wörthersee: The first GTI meeting starts at Volkswagen headquarters

Pecco Bagnaia (Ducati): Testing on the new Panigale/MotoGP

From autumn onwards, U2 will be playing again at Karlsplatz.